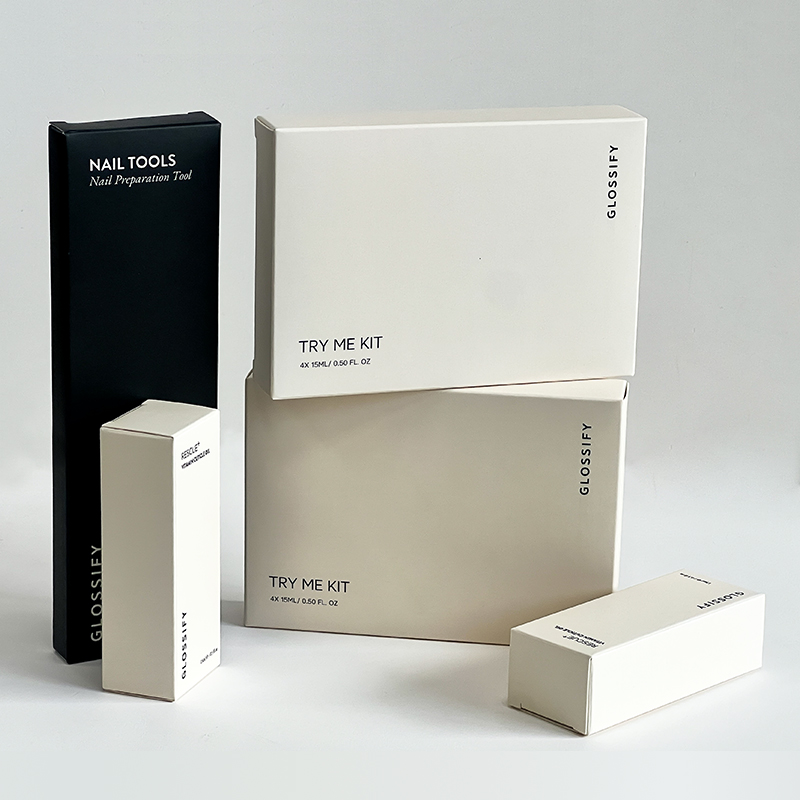

Among printed products, custom packaging is one of the most complex to prototype. Unlike brochures—where digital machines can deliver prototypes in minutes—printing surface paper is just a small part of custom packaging prototyping. Custom packaging also requires lamination and gluing, making its prototyping far more intricate.

The biggest challenge in custom packaging prototyping lies not in lamination or gluing, but in material preparation. After printing, surface paper needs precise cutting and creasing; gray board, the core structural material, must be sized and V-grooved. Surface paper cutting relies on either die-cutting plates or cutting plotters with pre-set lines, both demanding meticulous setup. For V-grooving, a dedicated manual machine simplifies the process, but without it, adjusting large production machines (a time-consuming, skilled task) is necessary.

Only after material preparation can lamination and gluing proceed. Every custom packaging prototype requires significant labor and cost, especially complex designs needing custom die-cutting plates, which further raise prototyping costs.

For professional custom packaging prototyping solutions that address these challenges efficiently, feel free to contact Shengcai Printing. A key advantage of working with us is that we offer free samples—with the sample cost deducted when you place the bulk order. We specialize in prototyping various types of packaging, ensuring precision and cost-effectiveness for your projects.

发表回复