1. Why Focus on Gift Box Customization?

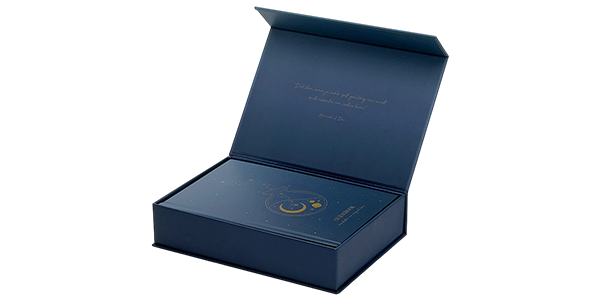

For brands, high-quality gift boxes are not just product carriers but also key to conveying brand tone—2025 e-commerce industry reports show that customized gift boxes can increase product repurchase rates by 32%. However, many businesses easily fall into the misunderstanding of “only focusing on appearance” during customization; in fact, a scientific customization process needs to cover all links. Below are the detailed methods for packaging manufacturers to customize gift boxes.

2. 4 Core Stages of Gift Box Customization (with 2025 Latest Standards)

Stage 1: Demand Communication & Confirmation – Key to Avoiding Later Rework

This step is the foundation of customization. Many manufacturers have to modify samples more than 3 times due to insufficient communication, extending the delivery cycle.

- Clarify Core Needs: Confirm 4 key pieces of information with customers (Table 1), and proactively ask “whether logistics transportation adaptation is needed” (e.g., fragile products require additional shock-absorbing foam);

- Provide Professional Advice: Combined with the 2025 environmental trend, recommend degradable materials (such as corn starch-based cardboard). If the customer has a limited budget, suggest using “partial gold stamping” instead of “full-box gold stamping,” which reduces costs by 20% while maintaining texture.

Table 1: 2025 Gift Box Customization Demand Communication List

| Demand Category | Key Information to Confirm | Industry Reference Standard |

| Basic Parameters | Size (L×W×H), Quantity (≥500 pieces for wholesale price) | Error ≤2mm, free sampling fee for quantity ≥1000 pieces |

| Material Selection | White cardboard (commonly used), kraft paper (eco-friendly), specialty paper | Thickness ≥250g to prevent deformation |

| Process Requirements | Laminating (glossy/matte film), gold stamping (gold/silver/laser) | Gold stamping area ≤30% for a more refined look |

| Delivery Time | Reserve 3-5 days of buffer time (to deal with unexpected process issues) | 7-15 days delivery for regular orders |

Stage 2: Design & Prototyping – Visual Verification of Effects

- Design Principles: Balance aesthetics and practicality (e.g., box lid closure ≥90% to avoid easy falling off). The 2025 trend is “minimalism + prominent brand logo” to reduce redundant patterns;

- Prototyping Process: First, create a flat design → customer confirmation → produce physical samples (3-5 days). Samples should be marked with “material and process number” for customers to compare and confirm.

Thought: Why can’t prototype confirmation be skipped? In 2025, a food brand skipped the prototype stage and found that “the printing color of the box body deviated from the brand color by 15%” after mass production, resulting in a direct loss of 20,000 yuan in production costs.

Stage 3: Production & Processing – Control Details to Improve Quality

- Material Procurement: Prioritize FSC-certified eco-friendly paper (customer demand for eco-friendly materials increased by 45% in 2025);

- Core Process Handling (listed for clarity):

✅ Printing: Use UV printing (more vivid colors, friction-resistant) with color difference ≤ΔE2.0 (industry qualification standard);

✅ Die-cutting: Use CNC die-cutting machines for smooth, burr-free cuts;

✅ Assembly: Combine manual and machine work to ensure firm box bonding (bonded area can bear ≥5kg without falling off).

Stage 4: Quality Inspection & Delivery – Ensure Final Effects

- Inspection Standards (updated 2025):

① Appearance: No scratches, no bubbles, printing pattern alignment ≥98%;

② Structure: No box deformation, smooth opening and closing;

③ Sampling Inspection: Randomly sample 5% of samples per batch; delivery is normal if the unqualified rate ≤1%;

- Delivery Guarantee: Pack with corrugated cartons (to prevent transportation extrusion) and attach a “quality inspection report” for customer acceptance.

3. Frequently Asked Questions (Q&A)

Q1: Is small-batch customization (e.g., 100 pieces) supported for gift boxes?

A1: Yes, but a small batch (100-500 pieces) requires an additional 300 yuan sampling fee. For quantities ≥500 pieces, the sampling fee is waived. It is recommended to estimate the quantity based on sales volume to reduce costs.

Q2: If unsatisfied with the finished product, how will the manufacturer handle it?

A2: If it is due to the manufacturer’s reasons (e.g., inconsistent materials, process errors), free re-production is available; if it is due to changes in customer needs, part of the cost (such as the cost of printed materials) needs to be borne through negotiation.

发表回复